With over 25 years of experience in the valve and fittings industry, our Director,

Mr. ABID SAKRI, has been the guiding force behind ELAF

Valves. Under his leadership, the company has grown into a trusted manufacturer known

for precision, reliability, and global standards.

He strongly believes that infrastructure and people are the backbone of success. With continuous investment in advanced technology, skilled manpower, and modern facilities, he has shaped ELAF Valves into a future-ready enterprise capable of meeting the demands of industries worldwide.

ELAF Valves is a trusted name in the manufacturing of Industrial Valves and Pipe Fittings. With years of expertise, state-of-the-art infrastructure, and a commitment to quality, we deliver reliable solutions to industries worldwide.

Our company is driven by innovation, precision engineering, and strong ethical values, ensuring that every product meets international standards of safety and durability. With advanced technology and a skilled workforce, ELAF Valves continues to set benchmarks in the industry.

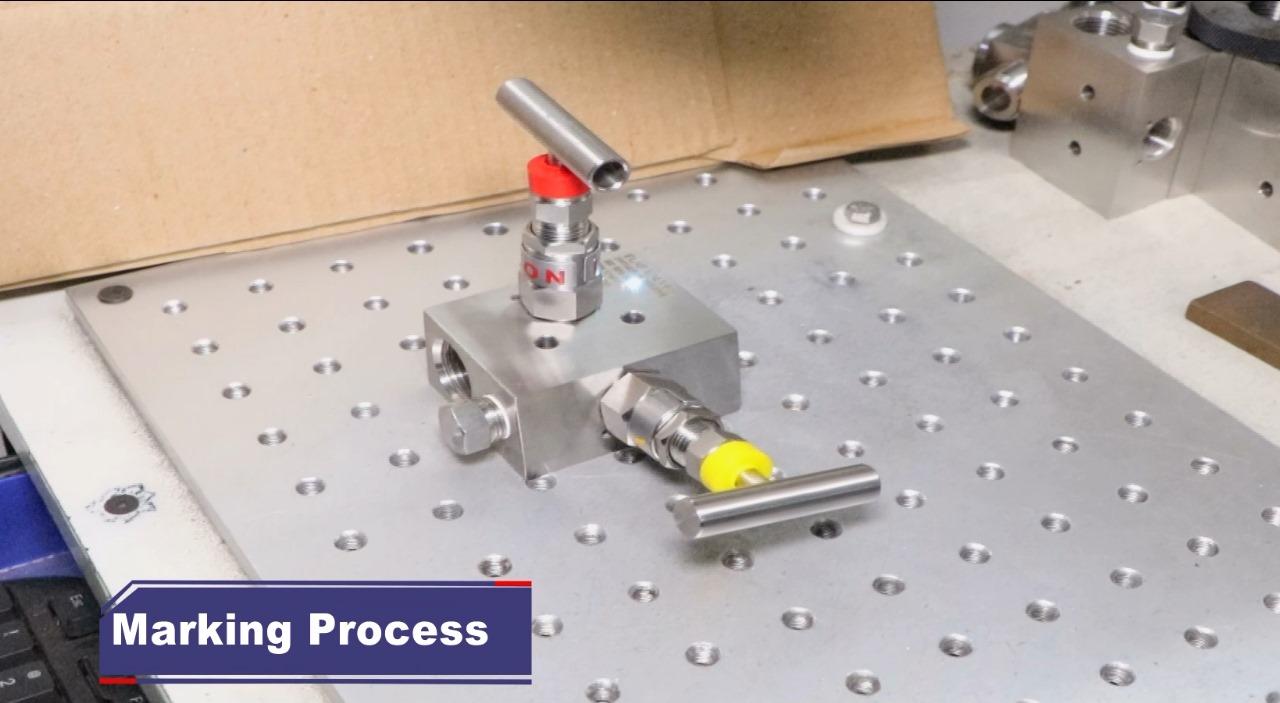

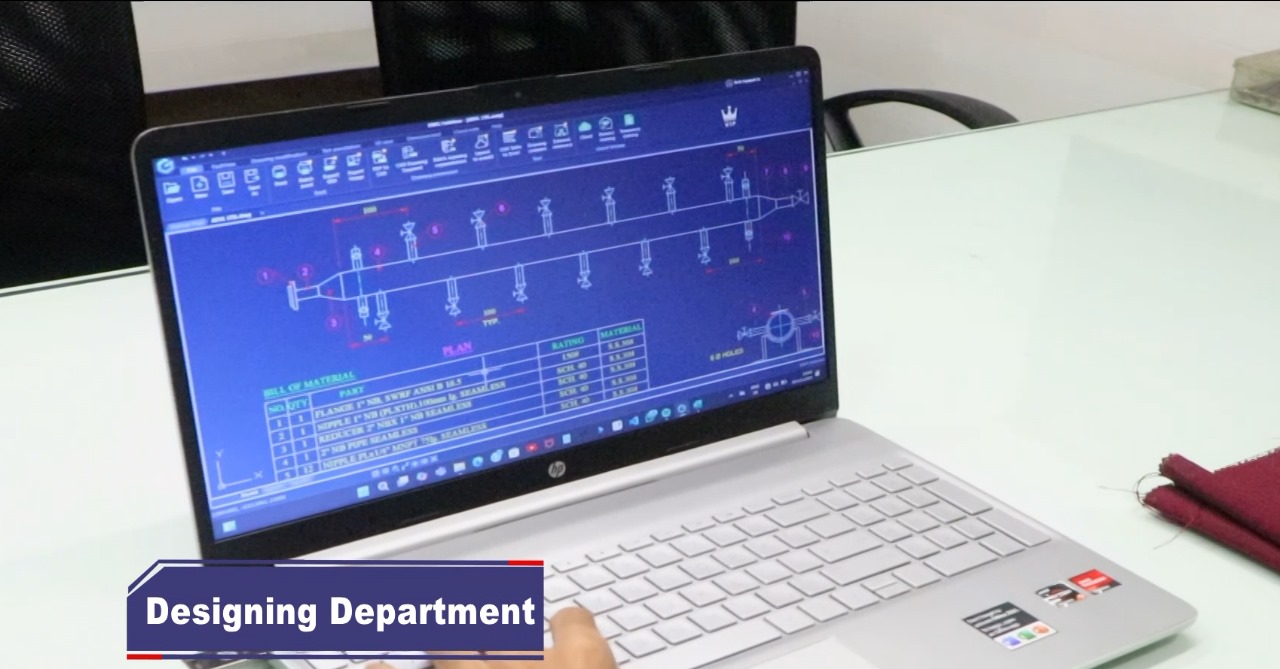

Our advanced manufacturing facilities are equipped with cutting-edge technology and modern machinery, enabling us to produce valves and fittings with exceptional precision and consistency. Every process is monitored closely to maintain international quality standards while ensuring efficiency and scalability.

Equipped with CNC machines, forging units, and automated welding systems.

High production capacity to meet large-scale industrial demands.

Strict adherence to lean manufacturing practices for efficiency.

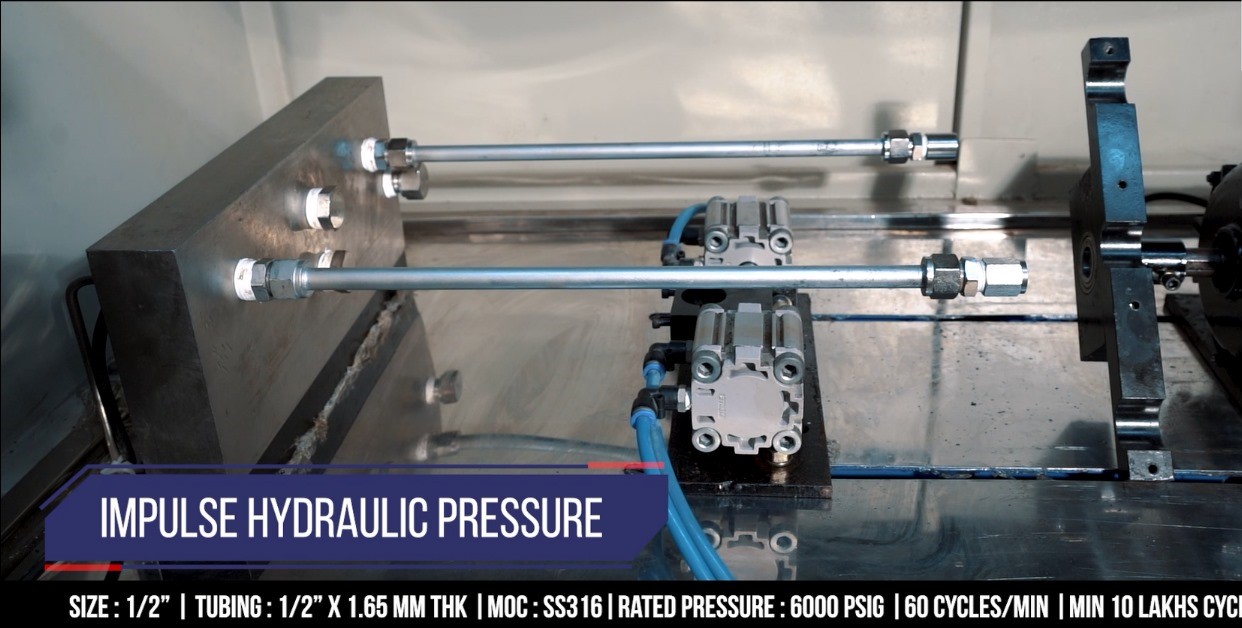

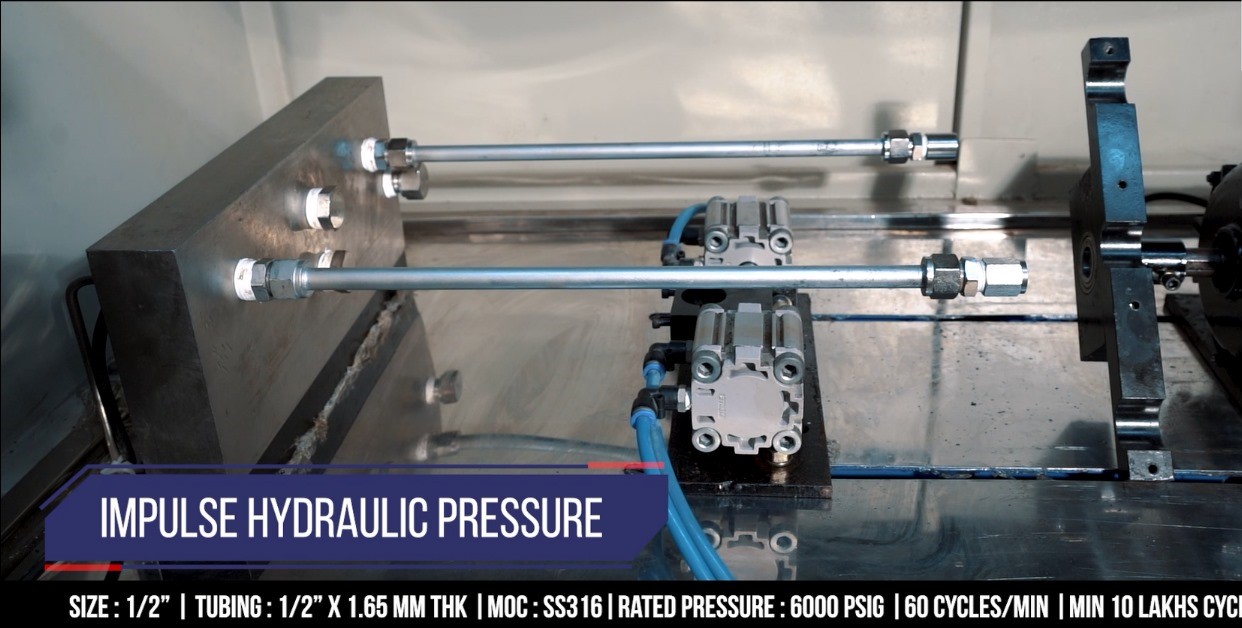

Our state-of-the-art testing machine is designed to validate the durability, safety, and performance of valves, fittings, and industrial components under the most demanding operating conditions. Built in compliance with ASTM F1387-99 (Reapproved 2012), it enables us to simulate real-world stresses and ensure that every product meets stringent international standards before it reaches our customers.

Impulse hydraulic pressure testing for extreme reliability under varying loads.

Flexure fatigue test to analyze endurance against repetitive stress cycles.

Rotary flexure test to validate rotational strength and long-term performance.

Vibration testing on 3 axes to ensure stability in dynamic industrial environments.